Category

- Lathe

- Gantry Type Milling Center

- Machining Center

- Radial Drilling Machine

- Boring Machine

- Surface Grinder

- Double Column Band Saw Machine

- Education Use Machine

- Conventional Lathe

- CNC Lathe

- Vertical Machining Center

- Hydraulic Surface Grinder

- High Precision Surface Grinder

- Bench Lathe for Metal

- Machine for Metal

- Manual Lathe Milling Machine

Woodworking Six Sides Automatic Cabine Panel Hole Drilling CNC Boring Machine

CNC-612 6-sided machining center 1. Crossbeam adopts through structure, boring operations on 6 sides are completed at on

Basic Info

| Model NO. | CNC-612 |

| Structure | Horizontal Drilling Machine |

| Layout | Horizontal |

| Controlling Mode | CNC |

| Automatic Grade | Automatic |

| Precision | High Precision |

| Warranty | 1 Year |

| Customized | Customized |

| Condition | New |

| Color | White |

| Dimension | 5800*2840*2200mm |

| Total Motor Power | 20.65kw |

| Voltage of Motor | 380V/50Hz |

| Transport Package | No Packaging |

| Specification | 3500kg |

| Trademark | TQS CNC |

| Origin | China |

| HS Code | 84659500 |

| Production Capacity | 10 Sets Per Month |

Product Description

CNC-612 6-sided machining center

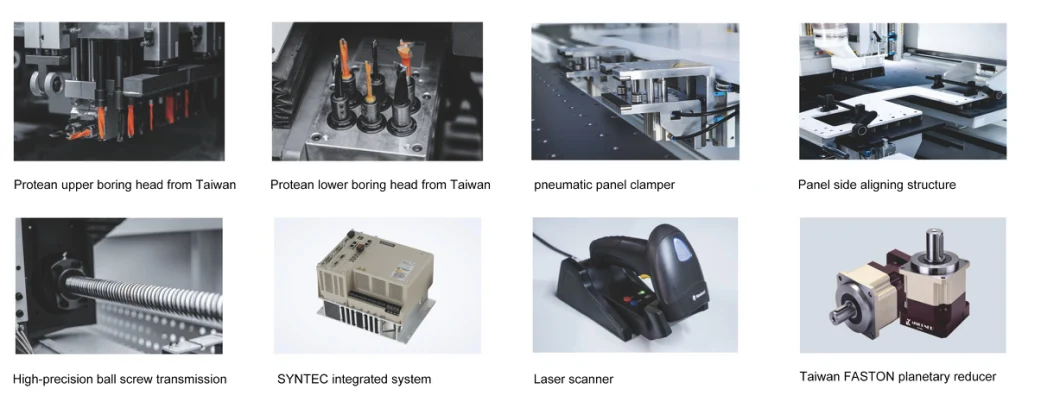

1. Crossbeam adopts through structure, boring operations on 6 sides are completed at one time.2. In order to achieve various processing, the machine adopts the combination of the boring head (horizontal + vertical) and individual spindle.

Application

Designed for customized panel board processing. Applicable for all types of boards for cutting material, six-sided drilling and double-sided slotting.

| Specifications | Model | CNC- / 612 |

| Travel Distance on Axis & Max. positioning speed | X-Axis | 5000mm & 130m/min |

| Y-Axis | 1500mm & 550m/min | |

| Z-Axis | 90mm & 30m/min | |

| U-Axis | 5000mm & 130m/min | |

| V-Axis | 1200mm & 80m/min | |

| W-Axis | 100mm & 30m/min | |

| A-Axis | 1260mm & 30m/min | |

| Z1-Axis | 90mm & 45m/min | |

| Y2-Axis | 1500mm & 55m/min | |

| Z2-Axis | 90mm & 30m/min | |

| Processing Range | Max. processing width (vertical) | 1200mm |

| Min. processing width (vertical) | 36mm / 50mm | |

| Max. processing length (vertical) | 5000mm | |

| Min. processing length (vertical) | 250mm | |

| Max. processing thickness (vertical) | 48mm | |

| Boring heads | Vertical boring heads | Lower: 9pcs, upper:12pcs |

| Horizontal boring heads | 8pcs | |

| Boring heads motor rotating speed | 3400 r/min | |

| Spindle power | 3.5kw | |

| Engraving spindle | Spindle type | Er25 |

| Spindle rotating speed | 18000 r/min | |

| Others | Working bench height | 960mm |

| Total power | 20.65kw | |

| Voltage | 380v 50hz | |

| Air pressure | 0.7-0.8Mpa | |

| Total weight | 3500kg | |

| Overall dimension | 5800x2840x2200 |

1. What's your guarantee? Which type after sale service can you provide to us?

All the machine, we can offer the 1 year guarantee to our customers; any parts damaged due to the quality issue, we will send the parts via DHL, Fedex or air shipment urgently.

After sale service: if you purchased our CNC nesting center or edge bander, and we don't have any dealer or agent in your region, we will send our engineer to your site for installation and training ( you should pay the round-trip flight ticket, salary of engineer- each day 100.00USD, also take charge of the local accommodation. ). Considering the situation, we can do the online training. Also any small issues, you can knock us online, we will offer the rapid action to your concerns.

2. Which type payment term can you accept? How could we keep our capital safe?

We can accept the T/T and L/C at sight. We have more than 10 years exporting experience, so we know more about the capital safty concern of our customer. We will offer the video call or pictures to your side, during our loading, then you can check what we have done for the loading, if any cheating, then you can control your payment (T/T or L/C).

3. What is the leading time, if we did the payment to your side?

The leading time of most common machines, will be 10-25 days after collecting the down payment / copy of L/C. Specially designed production will take little bit longer time.

4. Can you accept some O.E. M service to us? or any other service could you do for us?

We have more than 15 years experience in the woodworking machinery industry, also have more than 5 experienced engineers, so we can do the special design according to your requirement.

Also, our exporting team has more than 10 years of experience in this field, so they can help you to purchase relevant products, parts, or tools, which can save your time and your cost.