- Lathe

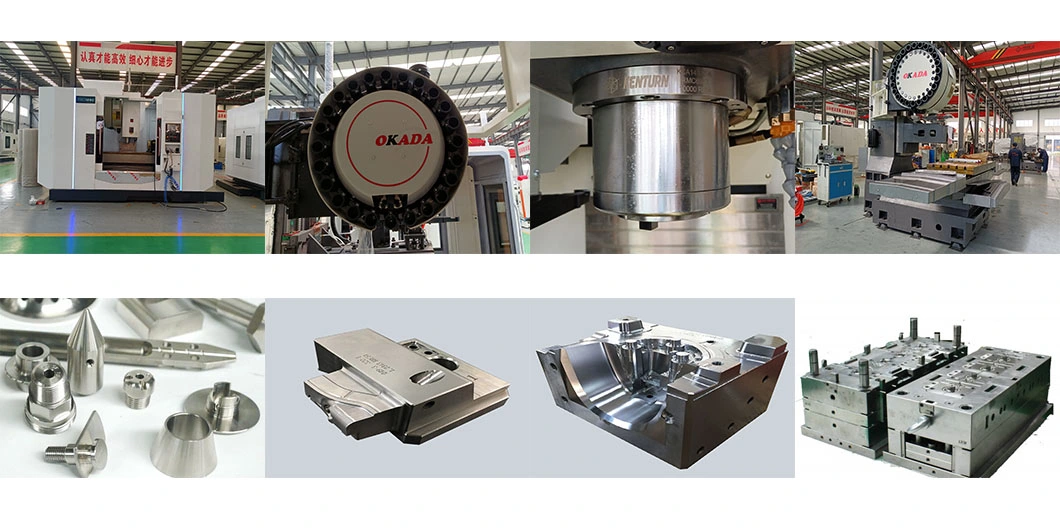

- Gantry Type Milling Center

- Machining Center

- Radial Drilling Machine

- Boring Machine

- Surface Grinder

- Double Column Band Saw Machine

- Education Use Machine

- Conventional Lathe

- CNC Lathe

- Vertical Machining Center

- Hydraulic Surface Grinder

- High Precision Surface Grinder

- Bench Lathe for Metal

- Machine for Metal

- Manual Lathe Milling Machine

Bymc Vmc1160 Vertical Machining Center High Precision 3/4/5 Axis Milling Machining Center

Basic Info

| Model NO. | VMC1160 |

| Process Usage | Metal-Cutting CNC Machine Tools, CNC Non-Conventional Machine Tools, Metal-Forming CNC Machine Tools |

| Movement Method | Contour Control |

| Control Method | Semi-Closed Loop Control |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.02~0.03(mm) |

| Performance Classification | Economical CNC Machine Tools |

| Certification | CE, ISO 9001 |

| Condition | New |

| X-Axis Travel | 1100 |

| Y-Axis Travel | 600 |

| Z Axis Travel | 600 |

| Workbench Size | 1200*600 |

| Maximum Load-Bearing Capacity of Worktab | 800/1100 |

| T-Slot (Number of Slots X Width X Spacin | 5-18-125 |

| Spindle Taper | Bt40-150 |

| Drive Manner of Spindle Type | Belt Type/Mechanical Gear |

| Spindle Motor Power | 11/15 |

| Spindle Speed | 8000/10000/12000(Directly Connected Motor) |

| Fast Moving (X/Y/Z) | 36/36/36 |

| Cutting Feed | 1-8000 |

| Three-Axis Rail Specifications | 45/45/45 |

| Feeding Motor(X/Y/Z) | 18/18/22 |

| Positioning Accuracy | 0.0075 |

| Transport Package | Wooden Case |

| Specification | 2820*2260*2550 |

| Trademark | BYMC |

| Origin | China |

| HS Code | 8457101000 |

Product Description

Basic characteristics of machine tools

On the basis of inheriting the advantages of traditional vertical CNC milling machines with strong rigidity, symmetrical structure, and strong stability, this machine tool introduces the international advanced dynamic rigid design concept and optimizes the design of moving parts. The machine tool has the characteristics of strong rigidity, large torque, and fast response characteristics, which is suitable for the needs of various mechanical processing fields such as automobiles, aerospace, and hardware.

The spindle adopts the Taiwan brand.

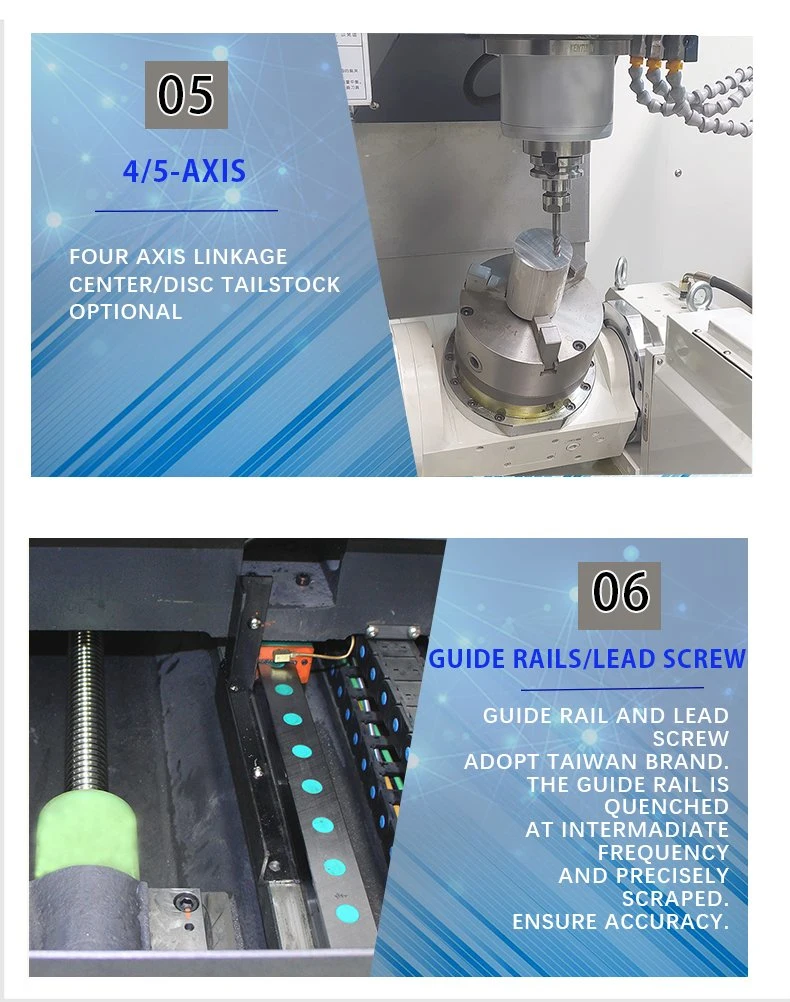

The three-axis movement adopts linear slide rails, and the three-axis rapid movement can reach 36 meters/min to ensure accurate positioning.

The machine bed, workbench, column, beam, saddle, and headstock are made of resin sand molding HT300 high-strength inoculated cast iron. After secondary annealing treatment, the casting stress and internal stress generated by rough machining are completely eliminated to ensure high structural rigidity and stability. High, to ensure quality permanently.

The castings are calculated and analyzed by computer based on the finite element analysis method. The reasonable structural strength and the matching of stiffening ribs provide high mechanical rigidity.

| Name | Unit | VMC1160A | VMC1160B | |

| Processing range | x-axis travel | mm | 1100 | 1100 |

| y-axis travel | mm | 600 | 600 | |

| Z axis travel | mm | 600 | 600 | |

| Workbench size | mm | 1200*600 | 1200*600 | |

| Maximum load-bearing capacity of worktable | kg | 800 | 1100 | |

| T-slot (number of slots x width x spacing) | mm | 5-18-125 | 5-18-125 | |

| Spindle taper | BT40-150 | BT40-150 | ||

| Drive manner of spindle type | Belt type/Mechanical gear | Belt type/Mechanical gear | ||

| Spindle motor power | kw | 11/15 | 11/15 | |

| Spindle speed | rpm | 8000/10000/12000(Directly connected motor) | 8000/10000/12000(Directly connected motor) | |

| Fast moving (X/Y/Z) | m/min | 36/36/36 | 36/36/36 | |

| Cutting feed | mm/min | 1-8000 | 1-8000 | |

| Three-axis rail specifications | mm | 45/45/45 | 45/45/45 | |

| Feeding motor(X/Y/Z) | NM | 18/18/22 | 18/18/22 | |

| Distance from spindle nose to table surface | mm | 140-740 | 140-740 | |

| Vertical distance from spindle center to column guide surface | mm | 650 | 650 | |

| Tool diameter | mm | Φ78/φ120mm | Φ78/φ120mm | |

| Maximum tool length | mm | 300 | 300 | |

| Maximum tool weight | kg | 8 | 8 | |

| Positioning accuracy | mm | ±0.0075 | ±0.0075 | |

| Repeatability | mm | ±0.005 | ±0.005 | |

| Machine weight | kg | 6100 | 6300 | |

| Dimensions | mm | 3400x2480x2960 | 3400x2480x2960 | |

Q1: How is the warranty?

A1: Warranty time is 13 months after the BL date.

Q2:Can we visit your factory before ordering?

A2:Sure.All new and old friends are welcome to visit us at our factory. Besides, we can pick up you at the station or airport if needed. We will be very honored to help with tickets and accommodation booking.

Q3:Do you have a stock?

A3:Sorry, most of our machines don't have stock, we always produce according to order. However, if during fairs months, maybe have a few samples back from fairs.

Q4:What's the MOQ?

A4:One set only.

Q5:How about your quality?

A5:We have approved the ISO9001:2008 Quality management system.ISO14001 Environmental management system, OHSAS18001 International occupational health and safety management system, and Social Accountability 8000(SA8000). Most products have been approved by the European and American safety standards, including CE, GS, EMS&UL,90% of our products are exported to more than 60 countries and regions around the world, especially to Europe and the American market, and always win high reputation. So you can rest assured of our quality products and our best services.

Q6:Do you have professional engineers?

A6:Yes.we have professional engineers and designers. We can provide OEM services.

Q7:Can you provide customized machines?

A7:Yes, we can design and manufacture according to your specific requirements.