- Lathe

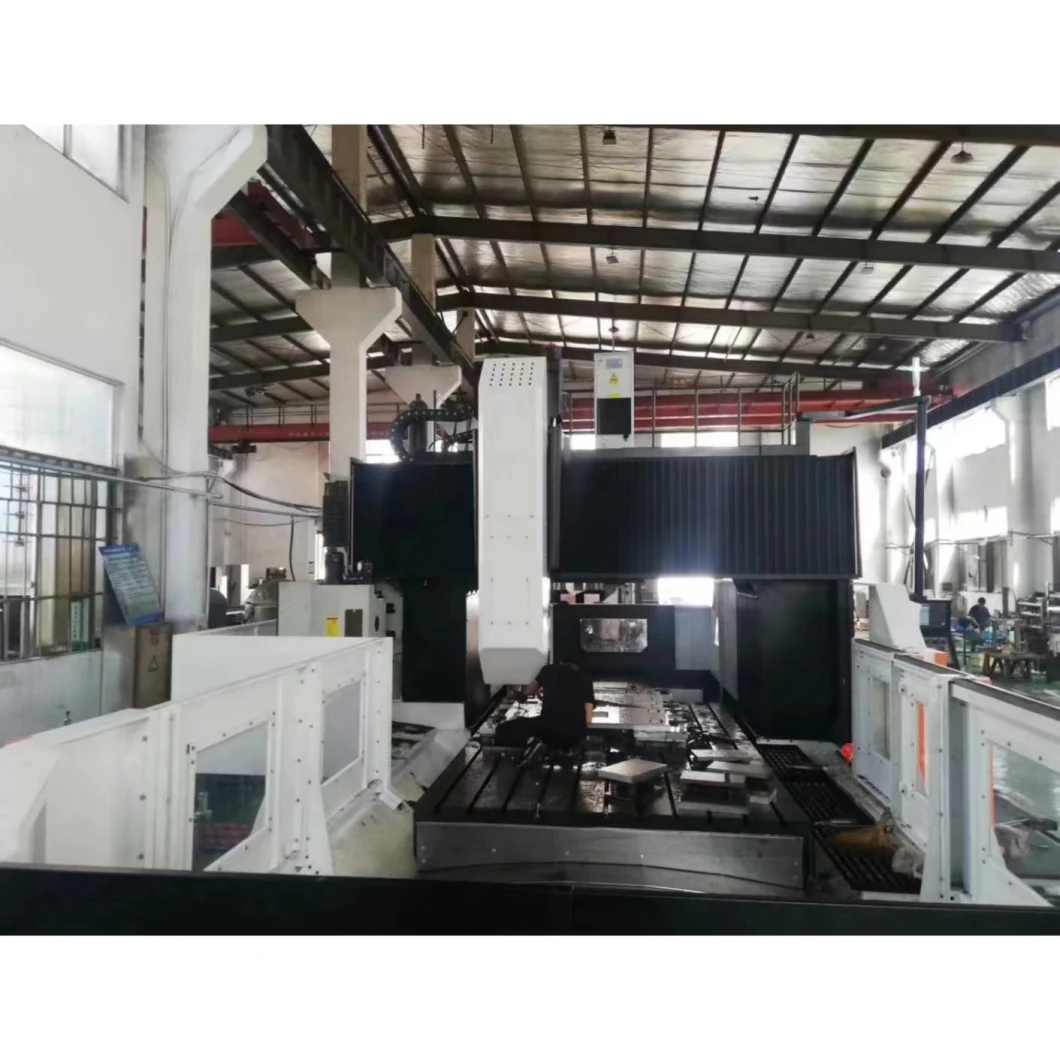

- Gantry Type Milling Center

- Machining Center

- Radial Drilling Machine

- Boring Machine

- Surface Grinder

- Double Column Band Saw Machine

- Education Use Machine

- Conventional Lathe

- CNC Lathe

- Vertical Machining Center

- Hydraulic Surface Grinder

- High Precision Surface Grinder

- Bench Lathe for Metal

- Machine for Metal

- Manual Lathe Milling Machine

China Hot Sale Elective CNC Control System Gantry Type Milling Machining Center with CE

Basic Info

| Model NO. | GMF-1210 |

| After-sales Service | Help Check |

| Warranty | 1 Year |

| Application | Metal |

| Process Usage | Metal-Cutting CNC Machine Tools |

| Movement Method | Contour Control |

| Control Method | Closed-Loop Control |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.01~0.02(mm) |

| Performance Classification | High-End CNC Machine Tools |

| Certification | CE, ISO 9001 |

| Condition | New |

| Transport Package | Plywood Case |

| Trademark | TAKUKAWA |

| Origin | China |

| HS Code | 8457101000 |

| Production Capacity | 150 Sets Per Year |

Product Description

GMF-1210

CNC gantry machining center is with frame structure, with grinding sliding guide, according to a good rigidity, strong shock absorption, processing a wide range of good stability, the machine with milling, boring, drilling (drilling, expansion, hinge), tapping, Countersink and other processing functions, can be equipped with a variety of accessories milling head, with manual change function, to expand the processing range of the machine, parts can be completed at the same time a number of processing steps.The product structure and process maturity, quality, and stability. Applicable to the aerospace, automotive, ship, printing, packaging, textile, mold, and other mechanical processing areas. Machine tools with high efficiency, high precision, high rigidity, and other characteristics, are the enterprise-efficient, high-volume parts of the ideal choice.

| Specifications | Units | GMF1210 |

| Table size | mm | 1300x820 |

| X axis travel | mm | 1250 |

| Y axis travel | mm | 1050 |

| Z axis travel | mm | 600 |

| Distance between spindle nose and worktable surface | mm | 150-750 |

| Width of gantry | mm | 1050 |

| T slot(number-width-pitch) | 5-18x160 | |

| Max. spindle speed | rpm | 12000 |

| Spindle taper | mm | BT40 (Optional:BT50 ) |

| Main motor power | kw | 7.5 |

| Guide rail type | Linear rail | |

| X/Y/Z rapid traverse speed | m/min | 20/20/20 |

| Max.table load | Kg | 900 |

| Cutting feed speed | m/min | 0.005-10 |

| Positioning accuracy | mm | 0.010 |

| Repeat positioning accuracy | mm | 0.006 |

| Machine weight | kg | 7200 |

| Overall dimension | mm | 3650x2500x3000 |

1. MOQ 1 set2. DELIVERY TIME It depends on the machine and model you choose. Mostly 2 months - 4months. All machines are 100% new and not used. 3. PAYMENT TERM T/T 30% down payment when order, 70% balance payment before shipment.4. WARRANTY PERIOD 13 months from the date of B/L, during the warranty period, daily damage parts will be supplied freely, the after sale service will be done by dealers . After warranty period, the spare parts will be supplied at factory price.5. Customized products

We can design and manufacture according to your specific requirements, such as change the CNC control systems, change the spindle nose taper, upgrade the standard motor and more. You do not have to hesitate to contact me.